The Ultimate Guide To Lean Manufacturings

Wiki Article

Some Ideas on Die Casting You Should Know

Table of ContentsSee This Report on ManufacturingAll About Die CastingUnknown Facts About Manufacturing IndustriesA Biased View of Hon Hai Precision

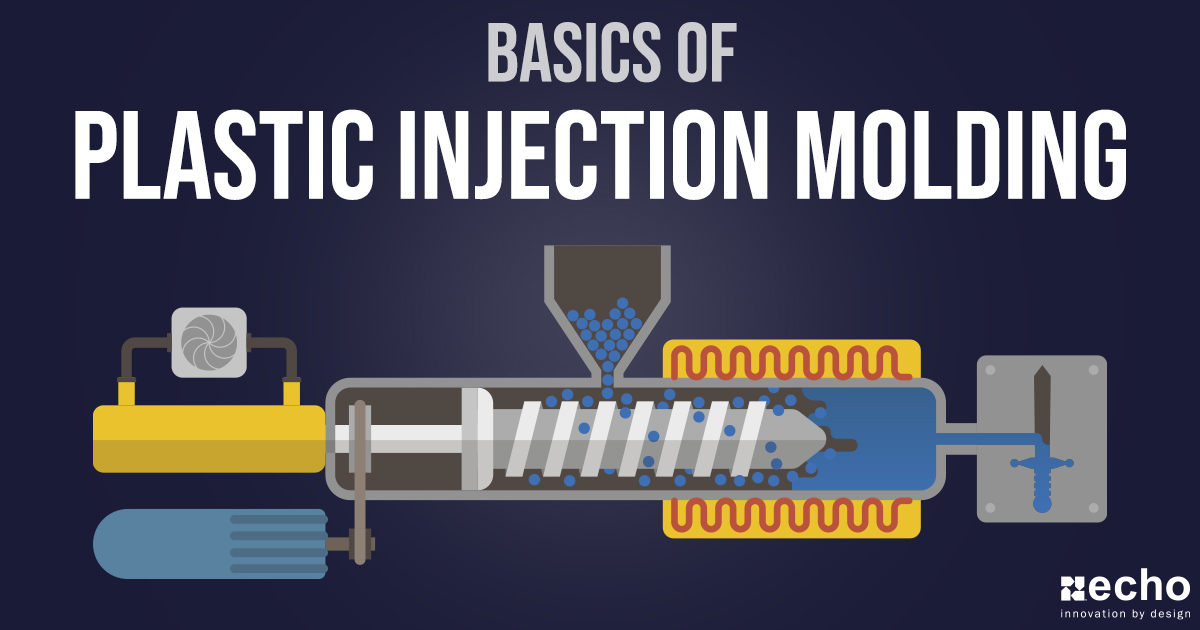

With injection moulding, pre-dried granular plastic is fed by a forced ram from a hopper right into a warmed barrel. As the granules are gradually moved ahead by a screw-type bettor, the plastic is pushed into a warmed chamber, where it is thawed. As the bettor advancements, the melted plastic is required with a nozzle that relaxes against the mould, permitting it to get in the mould cavity through an entrance as well as jogger system.The series of occasions throughout the shot mould of a plastic component is called the injection moulding cycle. The cycle begins when the mould shuts, complied with by the injection of the polymer into the mould cavity. Once the dental caries is loaded, a holding stress is preserved to compensate for product shrinkage.

When the dental caries is 98% complete, the maker changes from velocity control to pressure control, where the cavity is "packed out" at a continuous stress, where adequate speed to get to wanted stress is needed. This lets workers control component measurements to within thousandths of an inch or better. Like all commercial procedures, shot molding can create mistaken parts, even in toys.

The 10-Second Trick For Plastic Manufacturing

Trials are usually done prior to complete production runs in an initiative to anticipate problems as well as establish the suitable requirements to utilize in the shot process.: 180 When loading a new or unknown mould for the initial time, where shot size for that mould is unknown, a technician/tool setter may perform a dry run before a full production run.

Holding pressure is increased till the parts are complimentary of sinks and component weight has been accomplished. Injection moulding is an intricate modern technology with possible production issues. They can be caused either by problems in the moulds, or extra often by the moulding procedure itself.: 4785 Moulding defects Alternate name Summaries Causes Blister Blistering Elevated or layered area on surface area of the part Device or product is too warm, commonly caused by a lack of cooling around the tool or a faulty heating system.

like it

All about Plastic Manufacturing

Embedded particulates Foreign particle (burnt product or other) ingrained in the part Particles on the tool surface area, polluted product or foreign debris in the barrel, or excessive shear warmth shedding the material before injection. Circulation lines Directionally "off tone" wavy lines or patterns Injection speeds too slow-moving (the plastic has cooled way too much during shot, shot speeds must be set as rapid as is suitable for the process and also material utilized).Loading as well quickly, not enabling the sides of the component to establish. Also mould may run out registration (when the 2 fifty percents don't centre effectively as well as part walls are not the very same thickness). The provided info is the usual understanding, Modification: The Absence of pack (not holding) pressure (pack stress is used to pack out although is the component during the holding time).

Simply put, as the part diminishes the material separated from itself as there was not sufficient resin in the dental caries. Deep space can happen at any type of location or the component is not restricted by the thickness but by the resin flow and thermal conductivity, however it is most likely to happen at thicker areas like ribs or employers.

Knit line/ Blend line/ Transfer line Discoloured line where 2 flow fronts fulfill Mould or worldly temperature levels set also low (the material is cold when they meet, so they don't bond). Time for shift in between shot and also transfer (to packaging and also holding) is prematurely. Turning Distorted component Cooling is as well short, product is also warm, absence of cooling around the tool, inaccurate water temperature levels (the components bow inwards in the direction of the hot side of the tool) Unequal diminishing between locations of the component.

Indicators on Manufacturing You Should Know

125 inch wall surface density is +/- 0. 008 inch (0. 2 mm).: 446 Power requirements [modify] The power required for this process of injection moulding depends upon many points and ranges materials utilized. Production Processes Recommendation Overview states that the power demands rely on "a product's specific gravity, melting point, thermal conductivity, component dimension, and also molding rate." Below is a table from web page 243 of the same recommendation as previously mentioned that finest highlights the qualities relevant to the power needed for the most typically utilized products.In enhancement to mounting inspection systems on automatic devices, multiple-axis robots can eliminate components from the mould and also place them for more processes. Particular instances include eliminating of parts from the mould quickly after the components are developed, along with applying machine vision systems. A robot grips the part after the ejector pins have actually been expanded to release the component from the mould.

Why is injection molding machine production so efficient? As well as exactly how does it work? To discover, let's explore the subject tier 1 supplier and answer every one of the important inquiries, including what it is, the procedure behind it, its major benefits, and also how to choose the best provider. What is Injection Molding? is the procedure of using plastic to make a vast variety of parts as well as things.

The injection molding maker utilizes tailor-made molds to fill them out according to requirements, producing similar duplicates that can be tailored in a range of methods. What's even more, injection molding is a really flexible process, enabling a vast array of various materials and coatings, which makes it a preferred choice in countless sectors with totally various goals and also demands - additive manufacturing.

Report this wiki page